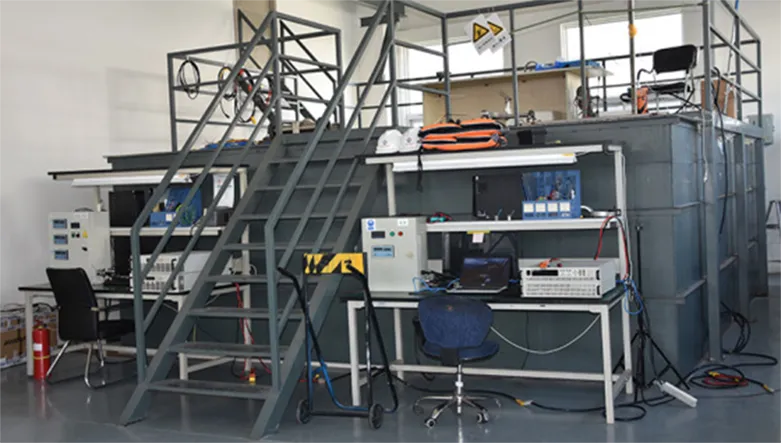

Water tank

For in-plant testing of outboard motors, the company has established a dedicated test pool. The pool is 10 meters long, 7.3 meters wide, and 1.7 meters high. A total of 11 test stations are set up, which can be used for factory performance testing of 1-40KW outboard motors. Each of our machines needs to undergo strict testing before leaving the factory.

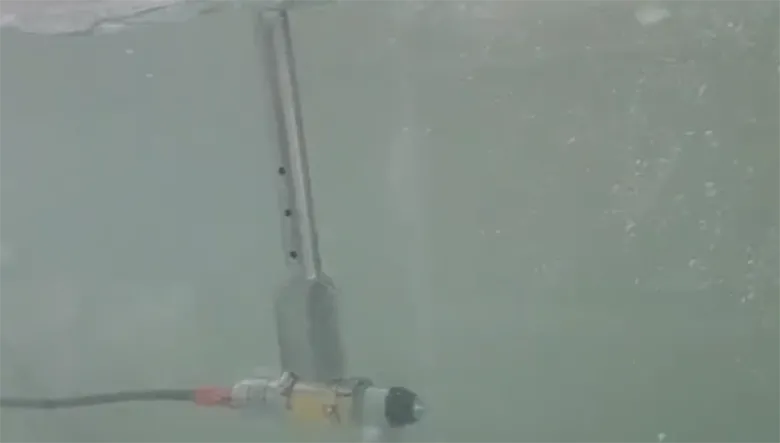

Circulating water channel

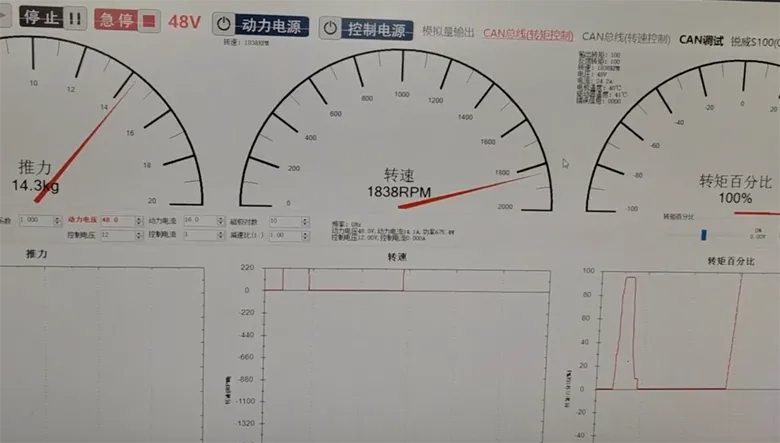

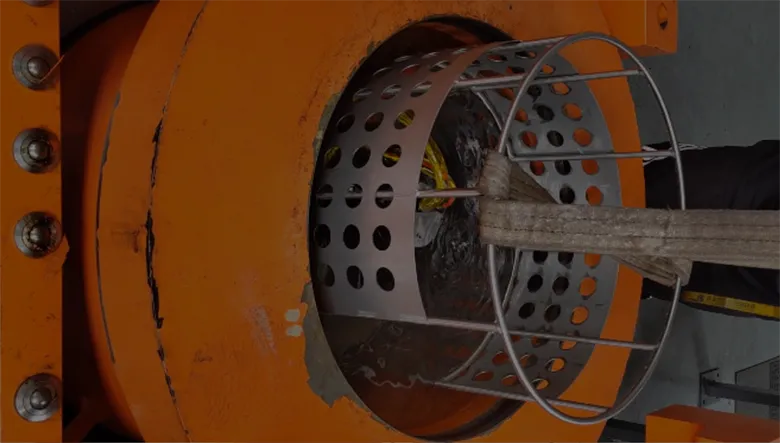

Test tank

Size: 6 m* 5 m*1.8 m. Divided into two sections.

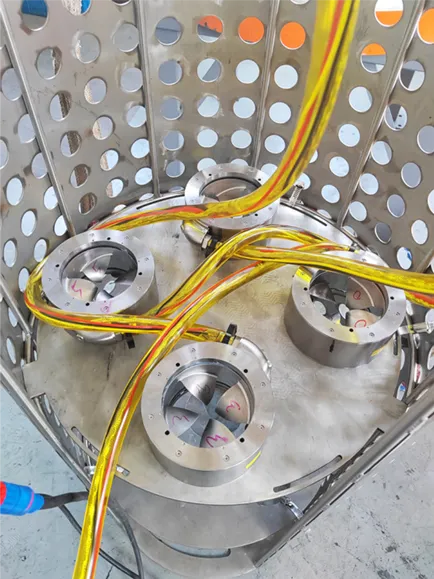

Equipped with three sets of mooring thrust test devices, it can test underwater thrusters with a maximum diameter of less than 600mm and a thrust of less than 500 kilograms or similar products.

High-pressure Container

Test Facility and Ability

The deep-sea environment simulation test device can simulate the water pressure intensity environment of 0-7,500 meters in the deep sea. It is widely used for pressure resistance strength and sealing performance tests of various products that need to work under deep-sea high-pressure intensity, such as submersibles, ROV, AUV, deep-sea detectors, waterproof cameras, etc. Equipped with an intelligent monitoring system, it can achieve water depth control with an accuracy of 1 meter and can be connected to external cables.

Function Interfaces

8 online monitoring ports

Pressure gauge port

Water injection port

Safety valve port

The deep-sea pressure simulation device has the following characteristics:

I. Pressure range

It can simulate pressures ranging from 0 to 75 MPa, which can meet the simulation requirements for different pressure conditions in the deep-sea environment.

II. Size specifications

With a diameter of 600 millimeters and a height of 1600 millimeters.

III. Functional characteristics

1.The rapid pressure increase and decrease function can achieve pressure adjustment in a short time and meet the requirements for rapid switching of different pressure states in experiments.

2.The cover can be opened and closed quickly in just 3 minutes, improving operational efficiency and facilitating the placement and removal of samples and the preparation of experiments.

3.The multi-stage hierarchical control function can finely adjust the pressure to adapt to different experimental needs.

Automatic pressure alternation can be set, which can simulate the complex pressure changes in the deep-sea environment and provide more realistic experimental conditions for researching materials and equipment in the deep-sea environment.

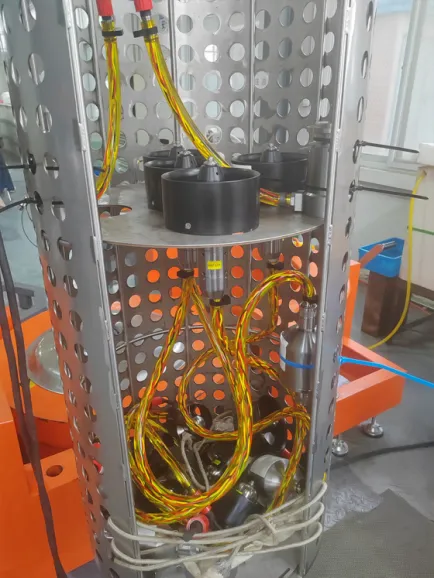

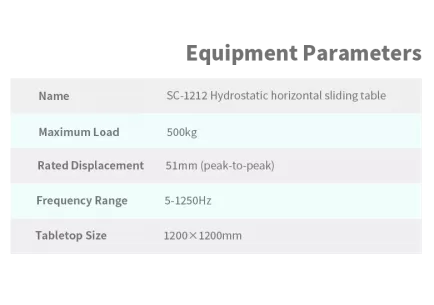

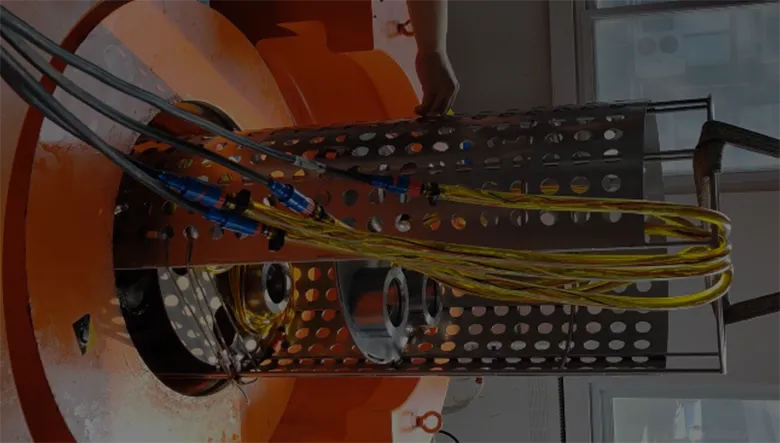

Hydrostatic horizontal sliding table

When the hydrostatic guideway is in operation, the pressure oil separates the moving parts and forms a uniform oil film. This greatly reduces friction, making the operation of the sliding table more stable and achieving extremely high positioning accuracy. In precision machining fields with strict requirements for accuracy, such as aerospace component manufacturing and optical lens processing, it can ensure that products meet high-precision standards.

Constant Temperature and Humidity Chamber

With advanced sensors and precise control systems, it achieves extremely high temperature and humidity control accuracy. It stably maintains target values in complex conditions, meets demanding needs like electronic component aging tests, and ensures reliable results.

CONTACT US NOW

A Better User Experience

We coopetate with a group of world-class scientific research practitioners, and delivered thousands of units, including Underwater thrusters, electric outboard, rotary actuators, and other products to our customers.

Many knowledgeable and realistic customers have given us a lot of recognition and support, which makes us more firm in the spirit of perfectionist craftsmanship, taking the boundaries of technology as our boundaries, and making unremitting efforts to pursue a better user experience.